During my years as an aviation consultant I was involved in the sourcing and supply of numerous business aircraft. I was also frequently engaged to perform aircraft valuations and Pre-Purchase Inspections (or Pre-Buys) as our American cousins tend to call them.

Why Commission a PPI

The value of commissioning a Pre-Purchase Inspection (PPI) cannot (in my opinion) be over-emphasised.

Just some of the benefits include:

I have said it many times and will say it again .. if you are buying an aircraft, even a small one, commission a Pre-Purchase Inspection - for your own benefit!

Misplaced Trust

Some of my clients were victims of costly disappointments they had experienced through their own aircraft purchasing efforts (before appreciating the value of PPI's) and I asked each of them about this and why, specifically, they had not commissioned a PPI.

A recurring theme I discovered was the trust my clients had attributed to the seller. In many cases my clients had approached a 'jet sales' organisation or an FBO they had used while chartering; then told them that their business wanted to purchase an aircraft and simply followed whatever advice/recommendation they received. I also noticed how my clients trusted these organisations because "They deal with aircraft for other successful individuals and businesses, so they must be okay!".

Part of the 'issue' is that in some cases it isn't about the trust-worthiness of a particular sales organisation or operator but about the fundamental difference in the levels of conformance required between aircraft and vehicle maintenance (for example) and which, for some clients, is their only point of reference.

For instance, a sales organisation may have little in-depth awareness of an aircraft's service history or current technical status while at the same time touting it as an "outstanding specimen."

As any professional would know, aircraft are subject to a continual stream of maintenance requirements which, the older the aircraft becomes, the more diligently one needs to track. One of the greatest potential dis-joins to this process occurs during changes in ownership - hence (again) the need for a PPI.

Types of PPI

The scope and cost of PPI's vary widely according to aircraft type and location and can quickly be affected by issues such as anomalies in the paperwork/log books or indeed anything which warrants further investigation.

Ball park figures for a single turbine skid gear helicopter should range anywhere from €2,000 to €5,000 depending on the level of inspection desired. If you limit the inspection to one professional, typically a mechanic (or engineer), to perform an 'overview' of airframe, engine and dynamic components as well as a 'scan' of the logs then you should be able to wrap-up the job in a day and stay within €2,000, perhaps even slightly less.

That service (above) was not however the service I provided.

The PPI's I conducted generally ran into the tens of thousands - anywhere from €8,000 to €30,000 .. sometimes more, plus expenses, and could last a week. For this the client would get three certified mechanics (engine, airframe and avionics), one or more qualified pilot/s, plus myself.

I issued a 'Certificate of Inspection' based on a thorough examination of the aircraft, from nose-to-tail as well as full testing of all the aircraft's systems both on the ground and in flight. On anything but the newest aircraft the engines were borescoped as a matter of principle.

All engine, airframe and flight logs were meticulously inspected as was compliance (or non-compliance) with every AD and SB since the aircraft's date of manufacture. All manuals and their supplements were checked for validity and a full review of the aircraft's flying history, maintenance history and hangarage/storage arrangements was also conducted.

The 'follow-up' to some of these PPI's could last several weeks as we sourced and collated accurate information relating to the aircraft's maintenance and operating history.

Real Value

The anomalies, omissions and defects (grouped into categories) raised in almost every one of our inspections would hand my customers an effective bargaining chip with which to negotiate the final terms of the aircraft's acquisition resulting not only in a compliant aircraft but, additionally, a lower purchase price the savings of which exceeded our healthy fees.

Notwithstanding the above, everything needs to be viewed in perspective. A relatively inexpensive light single helicopter where you have been personally familiar with its operations and maintenance may not warrant much more than the 'once over' outlined earlier. But, as you move onto some of the more complex twins or mid-size business jets, verifying the aircraft's condition becomes increasingly important in terms of limiting your liability.

I can only add again .. always commission a PPI before you buy!

* * *

Here are some images taken from a PPI which I conducted on a GIII. The aircraft was advertised as a 'clean' specimen in 'exceptional' condition!

This was one of two occasions on which I was accompanied by my client.

With client during the PPI of a GIII

De-bonding and crazing of cockpit forward-facing windows

Loose panels. Insignificant really but sometimes an indication as to the general standard to which the aircraft has been cared for

More loose panels (remember the seller was presenting this aircraft for inspection)

External rubber seals de-bonding (not a good sign)

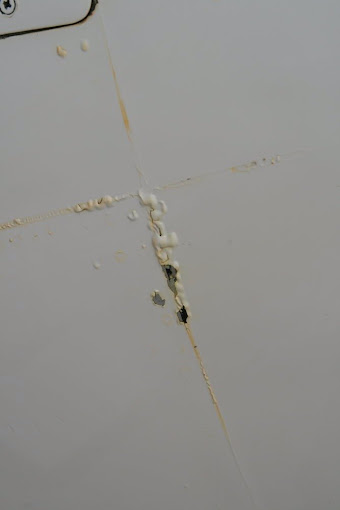

Corrosion on the underside of the lower tail section. In this case the corrosion had been left unattended for so long that it had penetrated the outer skin of the fuselage

One of the wheel wells highlighting multiple corrosion sites

Returning from the inspection with my client

Aside from the above concerns there were some alarming anomalies in the aircraft's paperwork and so, perhaps needless to say, this aircraft was rejected outright. Had my client purchased this aircraft without a PPI (based solely on its advertised 'good value') he would have bought himself a flying money-pit!

Why Commission a PPI

The value of commissioning a Pre-Purchase Inspection (PPI) cannot (in my opinion) be over-emphasised.

Just some of the benefits include:

- Verification of airworthiness leading to customer assurance and improved levels of safety

- Added-value attained through the findings of the PPI (either through work to be completed or modified purchase price)

- The 'no surprise' factor in future scheduled maintenance requirements

- Enhanced re-sale value when matched with ongoing professional service records

I have said it many times and will say it again .. if you are buying an aircraft, even a small one, commission a Pre-Purchase Inspection - for your own benefit!

Misplaced Trust

Some of my clients were victims of costly disappointments they had experienced through their own aircraft purchasing efforts (before appreciating the value of PPI's) and I asked each of them about this and why, specifically, they had not commissioned a PPI.

A recurring theme I discovered was the trust my clients had attributed to the seller. In many cases my clients had approached a 'jet sales' organisation or an FBO they had used while chartering; then told them that their business wanted to purchase an aircraft and simply followed whatever advice/recommendation they received. I also noticed how my clients trusted these organisations because "They deal with aircraft for other successful individuals and businesses, so they must be okay!".

Part of the 'issue' is that in some cases it isn't about the trust-worthiness of a particular sales organisation or operator but about the fundamental difference in the levels of conformance required between aircraft and vehicle maintenance (for example) and which, for some clients, is their only point of reference.

For instance, a sales organisation may have little in-depth awareness of an aircraft's service history or current technical status while at the same time touting it as an "outstanding specimen."

As any professional would know, aircraft are subject to a continual stream of maintenance requirements which, the older the aircraft becomes, the more diligently one needs to track. One of the greatest potential dis-joins to this process occurs during changes in ownership - hence (again) the need for a PPI.

Types of PPI

The scope and cost of PPI's vary widely according to aircraft type and location and can quickly be affected by issues such as anomalies in the paperwork/log books or indeed anything which warrants further investigation.

Ball park figures for a single turbine skid gear helicopter should range anywhere from €2,000 to €5,000 depending on the level of inspection desired. If you limit the inspection to one professional, typically a mechanic (or engineer), to perform an 'overview' of airframe, engine and dynamic components as well as a 'scan' of the logs then you should be able to wrap-up the job in a day and stay within €2,000, perhaps even slightly less.

That service (above) was not however the service I provided.

The PPI's I conducted generally ran into the tens of thousands - anywhere from €8,000 to €30,000 .. sometimes more, plus expenses, and could last a week. For this the client would get three certified mechanics (engine, airframe and avionics), one or more qualified pilot/s, plus myself.

I issued a 'Certificate of Inspection' based on a thorough examination of the aircraft, from nose-to-tail as well as full testing of all the aircraft's systems both on the ground and in flight. On anything but the newest aircraft the engines were borescoped as a matter of principle.

All engine, airframe and flight logs were meticulously inspected as was compliance (or non-compliance) with every AD and SB since the aircraft's date of manufacture. All manuals and their supplements were checked for validity and a full review of the aircraft's flying history, maintenance history and hangarage/storage arrangements was also conducted.

The 'follow-up' to some of these PPI's could last several weeks as we sourced and collated accurate information relating to the aircraft's maintenance and operating history.

Real Value

The anomalies, omissions and defects (grouped into categories) raised in almost every one of our inspections would hand my customers an effective bargaining chip with which to negotiate the final terms of the aircraft's acquisition resulting not only in a compliant aircraft but, additionally, a lower purchase price the savings of which exceeded our healthy fees.

Notwithstanding the above, everything needs to be viewed in perspective. A relatively inexpensive light single helicopter where you have been personally familiar with its operations and maintenance may not warrant much more than the 'once over' outlined earlier. But, as you move onto some of the more complex twins or mid-size business jets, verifying the aircraft's condition becomes increasingly important in terms of limiting your liability.

I can only add again .. always commission a PPI before you buy!

* * *

Here are some images taken from a PPI which I conducted on a GIII. The aircraft was advertised as a 'clean' specimen in 'exceptional' condition!

This was one of two occasions on which I was accompanied by my client.

With client during the PPI of a GIII

De-bonding and crazing of cockpit forward-facing windows

Loose panels. Insignificant really but sometimes an indication as to the general standard to which the aircraft has been cared for

More loose panels (remember the seller was presenting this aircraft for inspection)

External rubber seals de-bonding (not a good sign)

Corrosion on the underside of the lower tail section. In this case the corrosion had been left unattended for so long that it had penetrated the outer skin of the fuselage

One of the wheel wells highlighting multiple corrosion sites

Returning from the inspection with my client

Aside from the above concerns there were some alarming anomalies in the aircraft's paperwork and so, perhaps needless to say, this aircraft was rejected outright. Had my client purchased this aircraft without a PPI (based solely on its advertised 'good value') he would have bought himself a flying money-pit!